1-5L Single Layer Pyrex Borosilicate Tank Stirred Heated Glass Reactor

Description

Basic Info

| Model NO. | NBF-1L |

| Material | Glass-Lined |

| Capacity | <50L |

| Structure | Movable |

| Pressure | Negative |

| Agitator Model | Anchor Agitator |

| Tower Reactor Type | Glass Reactor |

| Heating | Oil Circulation Heating |

| Heat Transfer Structure | Inner Coil Type |

| Automatic Grade | Automatic |

| Condition | New |

| Product Name | 1-5L Single Layer Pyrex Borosilicate Tank Stirred |

| Glass Material | High Borosilicate Glass |

| Rector Type | Single Glass Reactor, Reaction Vessel |

| Application Areas | Pharmacy,Biological,Lab,Chemical |

| Function | Stirring Mixing,Vacuum,Distillation and Reflux,Co |

| Material of Agitated Stirrer | PTFE |

| Optional Type | Heater, Chiller, Vacuum and Ex-Proof |

| Certificate | CE |

| Heating Power | 1.5kw |

| Motor Power | 40W |

| Stir Rod Diameter | 8mm |

| Vacuum | -0.098MPa |

| Port No. of Reactor Cover | 5 |

| Frame Material | Stainless Steel |

| Speed Control | Electronic Stepless Speed Regulation |

| Transport Package | Wooden Cases |

| Specification | CE, ISO confirmed |

| Trademark | NANBEI |

| Origin | Zhengzhou, China |

| HS Code | 8419899090 |

| Production Capacity | 10000 Sets/Month |

Packaging & Delivery

Package size per unit product 100.00cm * 48.00cm * 48.00cm Gross weight per unit product 35.000kgProduct Description

1-5L Single Layer Pyrex Borosilicate Tank Stirred Heated Glass ReactorProduct Description

Description:

Single-layer glass reactors are mainly used in the testing and production of pharmaceutical, chemical, biological products and other industries. This product is under the vacuum negative pressure condition, using the principle of constant temperature heating and constant speed stirring to uniformly stir the raw materials, so that the materials can fully react, evaporate, separate, and recover the solvent in the kettle body, and all the parts in contact with the materials are resistant. High temperature, corrosion resistant borosilicate glass and PTFE materials are especially suitable for the reaction of easily decomposing denatured biological products, and are not easy to react with various materials.

Under the vacuum negative pressure condition, the stirring rod is stirred at a constant speed by using the speed-regulating knob, so that the material is fully reacted in the kettle body, and the material in the kettle is uniformly heated and evaporated at high speed by the intelligent constant temperature water (oil) bath. The solvent vapor produced in the solution is rapidly cooled, distilled or refluxed via a cooling coil of a glass condenser.The single-layer glass reactor has the main capacity of 1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 100L. 10 to 10 liters are equipped with universal casters for easy movement, and have a lower discharge function and a kettle. Temperature display function.This product can be used together with the vacuum pump to improve work efficiency; it can be used together with the low-temperature coolant circulating pump to improve the recycling efficiency. Customers are advised to purchase matching equipment.

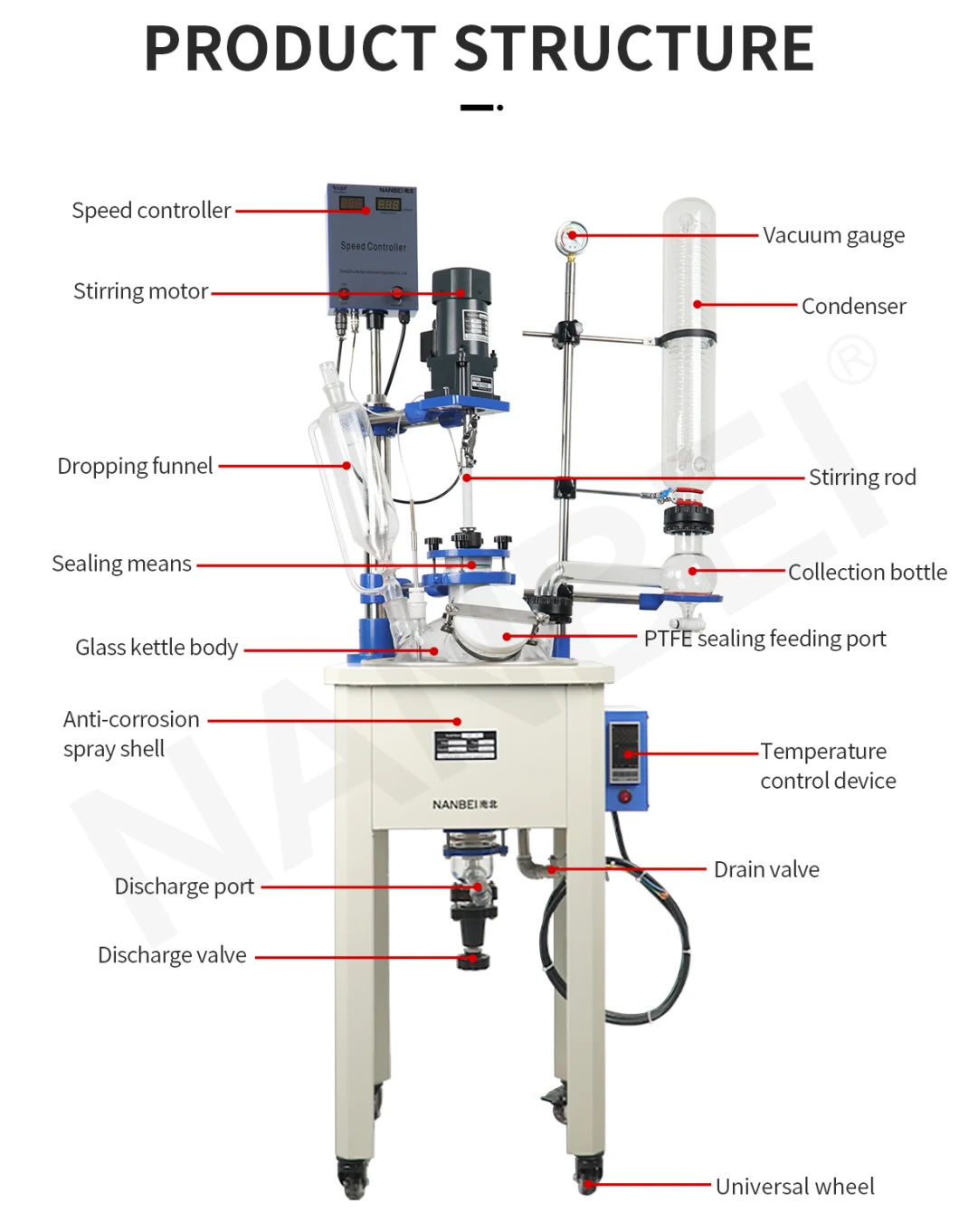

Structure Instructions

Detailed Photos

Product Parameters

| Basic specification | Name | Single layer glass reactor | |||

| Volume | NF-1L | NF-2L | NF-3L | NF-5L | |

| Glass material | GG-17 | ||||

| Frame material | Stainless steel | ||||

| Port No. of reactor cover | 5 | ||||

| Temperature range | .-80 to 250degree | ||||

| Vacuum | 0.098Mpa | ||||

| Stirring speed | 0-800pm | ||||

| Stir rod diameter | 8mm | ||||

| Motor power | 40W | 90W | |||

| Heating power | 1.5KW | 2KW | |||

| Voltage | 220V/50Hz | ||||

| Overall size (mm*mm*mm) | 320*330*1000 | 430*330*1200 | |||

| Plate size (mm*mm*mm) | 280*330 | 350*330 | 410*325 | ||

| Inner size (mm*mm) | stainless steel 280*170mm | ||||

| Package size (mm*mm*mm) | 800*480*450 | 1000*480*480 | |||

| Gross weight(KG) | 26 | 30 | |||

| Configuration list | Speed control mode | Electronic stepless speed regulation | |||

| Speed display mode | digital display | ||||

| Temperature display mode | digital display | ||||

| Seal mode | PTFE seal, ¢50 flange stir port | ||||

| Condensor | vertical 40*400mm standard 24# | vertical port 60*450mm standard 24# | |||

| Droplet port | 250ml constant pressure funnel, standard 24# | 500ml constant pressure funnel, standard 29# | |||

| Reduced pressure | NO | standard 24# Pressure release valve | |||

| Temperature tube | standard 19# | standard 24# | |||

| Vacuum display mode | Vacuum gauge | ||||

| Mixing connection | universal joint link | ||||

| Stir rod | Anchor type, Stainless steel rod with PTFE | ||||

Related Products

The double-layer glass reactor is mainly used for testing and production in the pharmaceutical, chemical, biological products and other industries. This product is under the vacuum negative pressure condition, using the principle of constant speed stirring to uniformly stir the raw materials, so that the material can fully react in the kettle body. The glass interlayer can be externally connected with high temperature circulation equipment to heat, evaporate, separate and recover the materials in the kettle. And other operations; external refrigeration cycle equipment can also be used to react to low temperature reaction in the kettle; if there is heating and cooling in the material reaction process, external high and low temperature circulation devices can be used. Moreover, the contact parts with materials are all made of high-temperature and corrosion-resistant high borosilicate glass and polytetrafluoroethylene material, which is especially suitable for the reaction of easily decomposing denatured biological products, and is not easy to react with various materials.Working Principle

Under the vacuum negative pressure condition, the stirring rod is stirred at a constant speed by using the speed-regulating knob, so that the material is fully reacted in the kettle body, and the heating or cooling reaction of the material in the kettle is indirectly heated by the glass interlayer external heating or cooling device, and the reaction process is heated during the heating process. The resulting solvent vapor is rapidly cooled, distilled or refluxed via a cooling coil of a glass condenser. After the reaction is completed, the material can be quickly discharged through the oblique discharge valve.

The double-layer glass reactor has the main capacity of 1L, 2L, 3L, 5L, 10L, 20L, 30L, 50L, 100L. all of which have the function of lower discharge. More than 10 liters are equipped with universal casters for easy movement and The temperature display function in the kettle.

It can be used together with the vacuum pump to improve the working efficiency; the cooling coil of the glass condenser can be used together with the low temperature coolant circulating pump to improve the recycling efficiency. Please purchase the matching equipment at the discretion of the customer. The kettle body interlayer can be equipped with heating, refrigeration equipment or high and low temperature circulation devices according to the material reaction requirements.

Packaging & Shipping

Company Profile

FAQ

FAQ:

Q1: Why Choose NANBEI ?

(1).Professional manufacturer with more than 13 years experience

(2).Exported to more than 97% Countries

(3).Turnkey Solution is no problem

Q2:OEM,ODM acceptable or not?

Absolutely Yes

Q3:What's kind of Payment terms for customer choosing?

T/T ,Western Union, Money Gram , Credit Card, Paypal , L/C ...

Q4:Can you visit your factory online?

Absolutely no problem

Q5:Can online video inspection before shipment?

Absolutely no problem

Q6: what's the MOQ ? Sample order is OK?

MOQ:1 set, sample order is no problem

Q7:What's kind of shipment for customer choosing?

Usually ship by sea, by air, by international express .

We can also provide reasonable solutions according to your transportation requirements

Q8:How to ensure product quality and after-sales service?

We have CE, ISO quality certificate, and SGS authentication.

After-sale service:

- Warranty : 1 year

- We supply free part for quality problem in warranty

- Long life technical support and service

Prev: Laboratory Chemical Autoclave Stainless Steel 100ml PTFE Liner Hydrothermal Synthesis Reactors

Our Contact