Wt-R 50L Glass Single Layer Jacketed Reactor for Crystallization

Description

Basic Info

| Model NO. | WT-R 50L |

| Warranty | 1 Year |

| Type | Fermentation Extraction |

| Material | Stainless Steel |

| Capacity | 50-100L |

| Agitator Model | Paddle Agitator |

| Heating | Electric Heating |

| Automatic Grade | Manual |

| Condition | New |

| Heating Transfer Area of Condenser(M2) | About 0.43 |

| Key Selling Points | Easy to Operate |

| After Warranty Service | Video Technical Support, Online Support |

| Motor Power(W) | 140 |

| Voltage | 110-240V~,50/60Hz |

| After-Sales Service Provided | Online Support |

| Warranty of Core Components | 1 Year |

| Vessel Jacket Capacity (L) | About 16.0 |

| Marketing Type | New Product 2020 |

| Frame | SUS304 |

| Video Outgoing-Inspection | Provided |

| Working Temp. Range (C) | -80~250 |

| Glassware Material | Borosilicate 3.3 |

| Power | 140 |

| Showroom Location | None |

| Transport Package | Wooden Box |

| Specification | 50L |

| Trademark | WEST TUNE |

| Origin | Zhejiang, China |

Product Description

West Tune High quality WT-R 50L Glass Single Layer Jacketed Reactor For Crystallization and Reaction

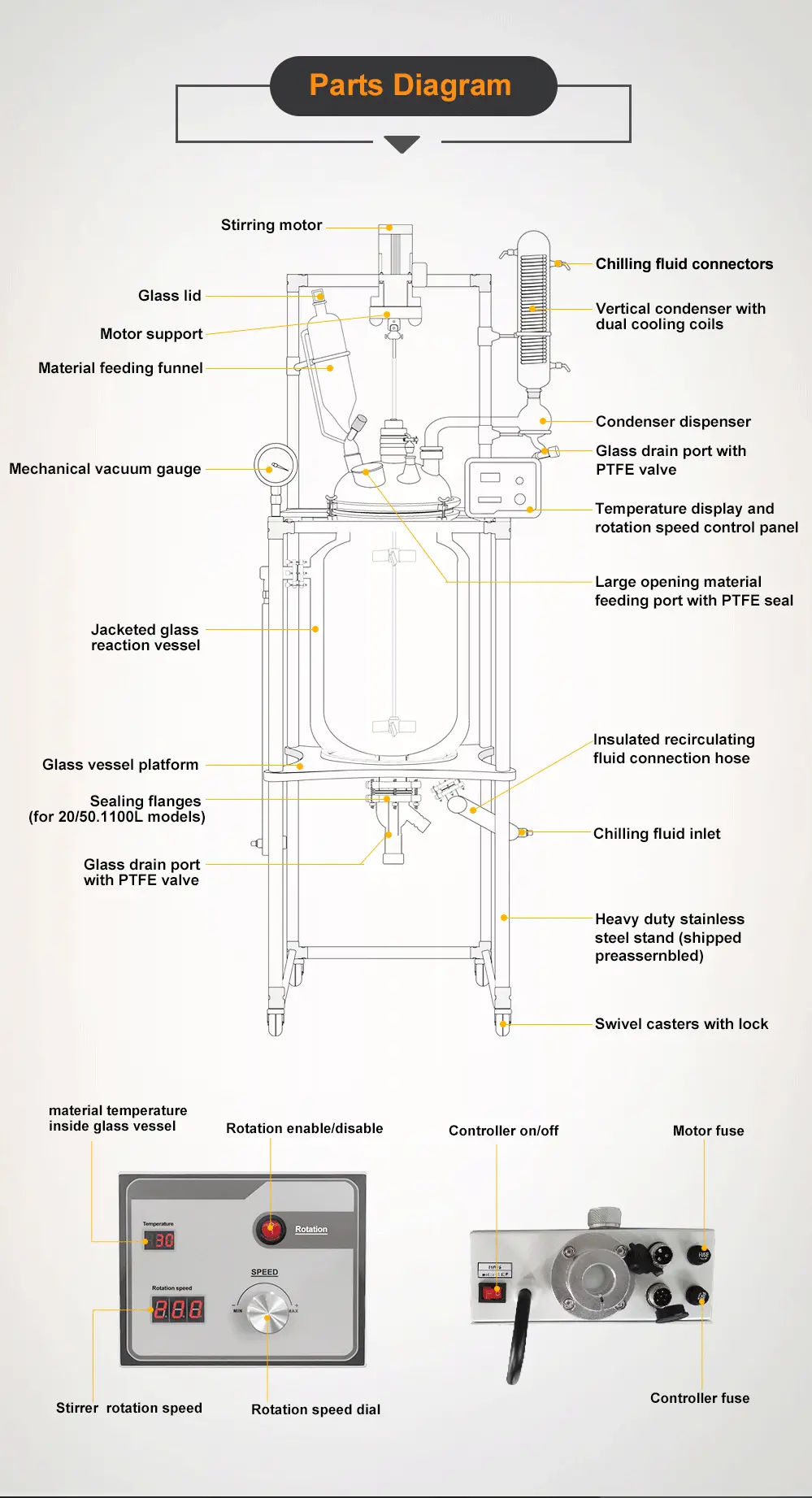

WT-R series single and dual jacketed glass reactors are designed for synthetic reactions of different materials while under a controlled temperature and vacuum environment. Each reactor features adjustable stirring speeds and a constant pressure feeding funnel, which allows you to add material to the vessel at a uniform and controlled speed. The built-in condenser makes it possible to recover some materials, also at a controlled rate of speed.

Features

High borosilicate glass has good physical and chemical properties. Wide working temperature range: -80 to 200. It can work under normal pressure and negative pressure, its vacuum degree can reach 0.1MPa. The vessel can bear the pressure range from -0.1MPa to 0MPa. PTFE and FV rubber material cock or discharge valve; Sealing together with PTFE covered O ring. Designed with vacuum gauge and temperature display unit.

Specification

Items | Specifications | |

Vessel capacity (L) | 50 | |

Vessel jacket capacity (L) | about 16.0 | |

Heating transfer area of condenser(m²) | about 0.43 | |

Feeding funnel capacity(ml) | 2000 | |

Lid cover | stirrer port | 50# flange |

temp. sensor port | 35# flange | |

condenser port | 50# ball-ground port | |

Liquid feeding port | 34# standard ground port | |

Feeding funnel port | 40# standard ground port | |

Solid feeding port | 80# flange | |

Glassware material | borosilicate 3.3 | |

Frame | SUS304 | |

Working temp. range (ºC) | -80~250 | |

Pressure range(mPa) | -0.1~0.0 | |

Jacket pressure tolerance(mPa) | ≤+0.03 | |

Motor power(W) | 140 | |

Speed adjustment | frequency control | |

Speed range(rpm) | 50~400 | |

Temp. sensor type | PT100 | |

Temp. accuracy(ºC) | ±0.1 | |

Thermo insulation hose connector | 1/2 male screw | |

Seal material | PTFE | |

Drain port height(mm) | about 450 | |

Stirrer type | Paddle, SUS304 with PTFE coated | |

Power supply | 110-240V~,50/60Hz | |

Operating temp. (ºC) | 5~35 | |

Ambient humidity (%) | ≤ 65 | |

Machine size (mm) | 900W×690D×2100H | |

N.W.(kg) | 82 | |

Company Profile

Our Service

Why Choose Us

FAQ

Our Contact