Lab Paddle Blender/ Stomacher Blender / Sterile Homogenizer

Description

Basic Info

| Model NO. | Lab Paddle Blender/ Stomacher Blender / Sterile Ho |

| Accuracy Grade | 0.5 |

| Load Way | Mechanical Load |

| Loading Method | Static Load |

| Display | Digital |

| Control | Manual Control |

| Weight | 0-100Kg |

| Power Source | AC220V |

| Oil Cylinder Position | Top |

| Model No. | Laboratory Overheated High Shear Homogenizer W |

| Certification | CE, ISO |

| Application Area | Chemical |

| Mixing Drum Shape | Conical |

| Operating Type | Continuous Operating |

| Name | Homogenizer Lab |

| Item | Lab |

| Product | for Making Body Cream, Lotion, Cosmeitcs |

| Matertial | Metal |

| Product Name | High Speed Homogenizer, Mixing, Blending |

| High Quality Lab Turbo Homogenizer Lab E | Hone Laboratory Equipment Automatic Digital Viscom |

| Laboratory Ultrasonic Homogenizer Emulsi | Lab Scale Homogenizer Portable Homogenizer Lab Equ |

| 5L Lab Rotary Extraction Equipment Mini | Lab Scale Vacuum Homogenizer Emulsifying Mixer Sm |

| Mixer Cosmetic Laboratory Vacuum Homoge | Sealing Pharmaceutical Medical Laboratory Equipmen |

| Lab Vacuum Emulsifier Small Lotion Mixer | Laboratory Small Cosmetic Cream Emulsion Plant, Ho |

| Transport Package | by Wooden Protect Box |

| Specification | customized |

| Trademark | AKFULUKE |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 1000 Per Year |

Product Description

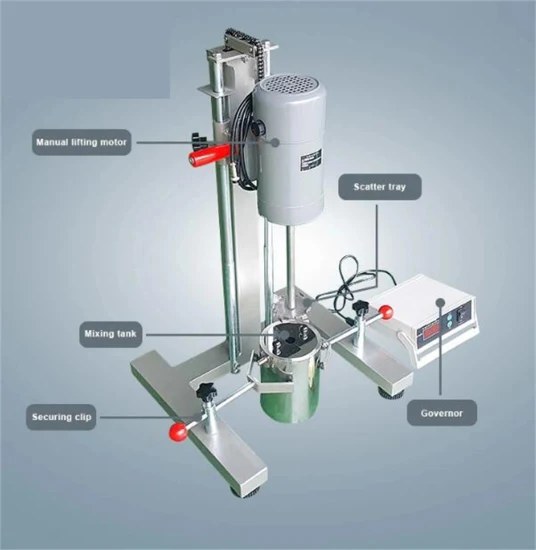

Lab Paddle Blender/ Stomacher Blender / Sterile Homogenizer

Product Description:

glass multifunctional laboratory homogenizing emulsifying mixer reactor machine includes working capacities of 1L, 2L, 5L and 10L. And the homogenizer speed is over 30000rpm. It can complete material dispersing, emulsifying, homogenizing and mixing processes under vacuum or pressurized conditions. It can intimate industrial production in laboratory by selecting high efficiency macro agitators, high shear homogenizing emulsifiers, vacuum seal system, and different sensor systems.The emulsifier adopts conbined standard structure, and with superior performance; which is the ideal laboratory equipment for researching developing new products in such industries as daily chemical care products, biopharmaceutical industry, paint and ink, nanometer materials, fine chemical industry, etcCorrosion resistance: Have strong corrosion resistance for various concentrations of inorganic acids, organic acids, organic solvents and weak alkali media.The whole reaction process of stirring, homogenizing, emulsifying, dispersing and mixing of materials can be observed in a glass kettle under vacuum or pressure conditions. It can measure the temperature, pressure, viscosity and PH of materials at the same time. Material can also be heated or cooled.Lifting Mode - Manual Balance/Electric Optional mixing slurry-anchor/dissolve/vane Reactor--Glass Reactor/Stainless Steel Reactor The parts which touches material is made of SUS304/SUS316L/PTFE.

Technical Parameter:

Voltage | 220V, 50/60Hz |

Glass tank volume | 1000/5000ml |

Maximum working temperature | 120ºC |

Vacuum | -0.08Mpa |

Maximum viscosity | 100,000CP |

Stirring motor | 120W |

Stirring speed | 10-100rpm |

Mixing paddle | SUS316L, Anchor propeller with silica gel scraping |

Homogeneous motor | 500W |

Homogenization speed | 8000-30000rpm |

Homogeneous head | US316L, 25KV-25G |

Machinery Seal | SIC, ceramic, imported form Switzerland |

O-ring material | FKM |

Upper cover | Homogeneous head, hopper, thermometer, vacuum gauge and connector, stirrer, three spare ports, rising height 270mm, vacuum connection port 10mm, glass jar jacket inlet and outlet diameter is 16mm. |

Note: In case of inconformity of the data in the table due to technical improvement or customization, the real object shall prevail.

After-sales Service

1.Warranty time: one year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely.But the travel and hotel expenses should be count on buyer.2. Commissioning services: the product's installation and commissioning at the demand side, our engineers will not leave there until get your agreement.3. Training services: our engineers will train your staff to operate it during the period of installation and commissioning,and they will not leave there until your staff can operate it properly and normally.4. Maintenance services: any malfunction happened, once you inquiry us, we will reply you within 48 hours except the special reasons.5. Lifelong services: we provide lifelong services for all the products we sold out, and supply the spare parts with discount price.6. Certificate services: we can provide related certificates to customers freely according to the request of customers.7. Inspection services: you can ask the third part inspection company or your inspector to inspect the products before shipment.8. The file: the Manual Specification, report of the material which used to the equipment and other documents related to the GMP authentication information will be provided by us.

RFQ

Q: Are you a factory?

A: Yes we are a factory with more than 20 years manufacturing experience. One is in Jiangsu,Another is in Guangzhou next to our office.

Q:I'm new in our industry,but I'm planing to set up a factory, what can I do?

A: We will design the most suitable proposal based on your actual situation, such as the daily production,raw material formula, factory layout, etc. Also we would like to intro- duce some excellent suppliers of raw materials, bottles,labels, etc if needed. After sales, engineer will be send to fields installation, training and commissioning.

Q:Are your machines difficult to operate? How do you teach us using the machine?

A: Our machines are fool-style operation design,very easy to operate.Besides,before delivery we will shoot instruction video to introduce machines'functions and to teach you how to use them.

Prev: Sorfa 500ml Lab Pes Vacuum Filter Medical Science Bottle Top Filter PVDF

Next: Xtlz260*200 Laboratory Disc Vacuum Compressed Air Pressure Filter

Our Contact