200L Electric Lifting Emulsification Machine Liquid Soap/Gel Homogenizer

Description

Basic Info

| Model NO. | MSE-200L |

| Certification | CE, ISO |

| Application Area | Pharmaceutical |

| Layout Type | Verticle |

| Mixing Drum Shape | Conical |

| Operating type | Continuous Operating |

| Condition | New |

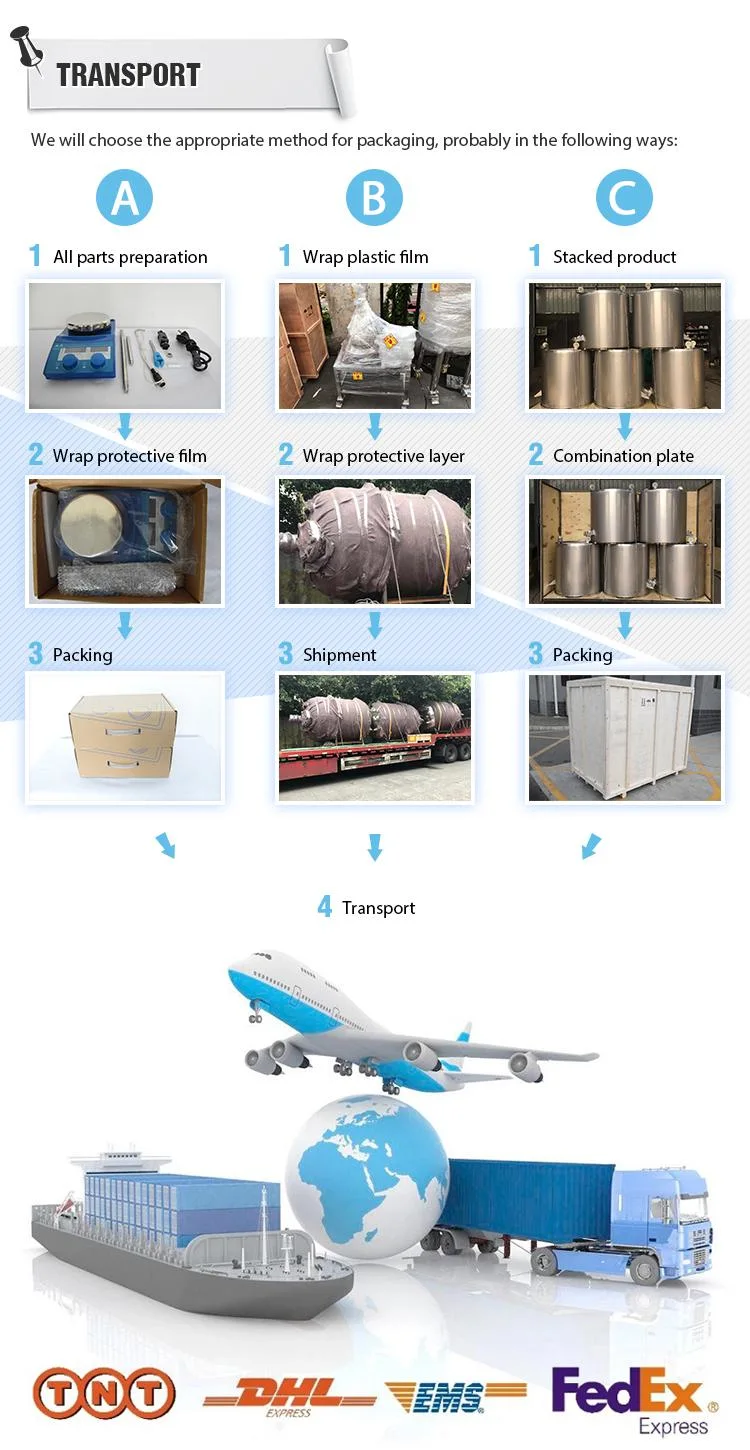

| Transport Package | Wooden Packing |

| Specification | MSE-200L |

| Origin | Guangzhou |

| HS Code | 8479820090 |

| Production Capacity | 1000 |

Product Description

200L Electric Lifting Emulsification Machine Liquid Soap/Gel HomogenizerIndustrial emulsifier chemical vacuum blender machine means that when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distributeone or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the machine effect. By the operation of hydraulic sheraing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be disperesed and emulsifed instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

Device configuration:

200l Homogenizer | |

Name | Material, name and specification |

Main pot | Total volume: 260L, working volume: 200L |

1. inner pot | 316L stainless steel |

2. stir paddle,stir axis | 316L stainless steel, frame scraping stirring, mechanical seal for reaction kettle |

3. Mixing motor | Power: 4kw, variable frequency speed regulation |

4. homogenizer | 316L stainless steel, 2800r / min, high speed mechanical seal |

5. Homogeneous motor | Power 11kw |

6. jacket | Stainless steel |

7. shell | 304 stainless steel |

8. lid | 316L stainless steel, sight glass hole, sight glass light hole, vacuum hole, pressure gauge hole, temperature detection hole, spice adding hole, mixing shaft hole |

9. Heating | Steam heating, design pressure 0.2MPa, service pressure ≤ 0.1MPa |

10. Thermal insulation cotton | Expanded perlite |

Electric control panel | The box is made of stainless steel, the surface is sand board, manual button control, digital temperature controller, total power is 15kw |

Process pipeline and valve | Stainless steel |

Frequency converter | |

Reducer | Cycloidal pin wheel reducer |

Equipped with one 50L oil bath and one 50L water bath | |

Reactor can be customized according to customer requirements

Application area

1. Daily Chemical & Cosmetics Industry:

such as baby cream, face cream, shaving cream, cream shampoo, toothpaste, cold cream, sunscreen cream, face cleanser, moisture cream, detergent, shampoo etc.;

2. Food Industry:

such as sauce, cheese, chocolate, cake gel, tomato paste etc;

3. Pharmacy Industry:

such as syrup, emulsion, emulsifier, ointment etc.;

4. Chemical Industry:

for chemicals mixing, heating, emulsifying, homgenizing etc.

Working principle

Precision fit of rotor and stator, claw structure of working head (rotor and stator forging manufacturing), bidirectional suction, high shear efficiency.

The intermittent high shear dispersive emulsifying homogenizer is a high-speed and stable rotation of the rotor to form high-frequency, strong peripheral tangent velocity, angular velocity and other comprehensive kinetic energy Efficiency: under the action of stator, strong and reciprocating hydraulic shear, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects are formed in the reasonably narrow gap between stator and rotor. The materials work in the container repeatedly and above, and finally the products are obtained.

Prev: Vacuum Freeze Dryer Household Mini Video Discount Candy Chocolate Fruit

Next: Xinchen Lab Double Chemical Jacketed Borosilicate Pilot Glass Reactor

Our Contact