1700c Electric Oven Industrial Laboratory 1200c Heat Treatment Muffle Furnace Price

Description

Basic Info

| Model NO. | STM-36-17 |

| Material | Stainless Steel |

| Type | Muffle Furnace |

| Working Temperature | 1600c |

| Heating Element | Molybdenum Disilicide (Mosi2) |

| Thermocouple | B Type |

| Transport Package | Standard Export Plywood Case |

| Specification | 1700C |

| Trademark | Saftherm |

| Origin | China |

| HS Code | 8514109000 |

| Production Capacity | 20000set/Year |

Product Description

1 Microprocessor based self-tuning PID control provides optimum thermal process with minimal overshoot.

2 Built-in ammeter and dual voltmeters for easy monitoring and troubleshooting.

3 Built-in computer interface.

4 Overheat protection shuts down the furnace if temperature is outside of acceptable range (refer to controller's manual) or when the thermocouple is broken or malfunctions.5 Power failure protection resumes furnace operation right after the point of failure when power is reestablished.

| Model | STM-3-17 | STM-6-17 | STM-8-17 | STM-12-17 | STM-20-17 | STM-36-17 | Customized | ||

| Chamber size(WxLxH)mm | 150x150x150 | 180x230x150 | 200x200x200 | 200x300x200 | 250x320x250 | 300x400x300 | Any size | ||

| Type | Benchtop | ||||||||

| Furnace structure | Chamber material, temperature controller system, heating element , furnace shell and other assistant parts | ||||||||

| Max temperature | 1700ºC | ||||||||

| Continue Operating Temp. | 1600ºC | ||||||||

| Power supply | 220V/4KW | 220V/5KW | 220V/5KW | 220V/6KW | 380V/7KW | 380V/15KW | Depends on size | ||

| Heating element | High quality MoSi2 rod | ||||||||

| Chamber material | High temperature polycrystal alumina ceramic fiber material | ||||||||

| Temperature precision | ±1ºC | ||||||||

| Thermocouple | B type | ||||||||

| Temperature controller | Electronic component | Schneider make | |||||||

| Heating rate | ≤ 15ºC/min ( suggest 10ºC/min for longer life using of furnace ) | ||||||||

| Safety protection | Overheat and thermocouple-break alarm | ||||||||

| Certification | ISO9001 CE SGS | ||||||||

| Furnace shell | high quality cold-rolled steel sheets CNC processing | ||||||||

| Insulation | High quality thermal insulation material to ensure a good uniformity | ||||||||

| Accessories | One pair of high temperature furnace gloves | ||||||||

| One pair of crucible stongs | |||||||||

| Optional | Paperless recorder | ||||||||

| Stainless steel exhaust chimney | |||||||||

| Alumina crucible | |||||||||

1.The muffle furnace was warped with enrivonmental plastic stretch film, then fixed well on the fumigation-free pallet

2.Tailored polywood case, coupled perfectly with the pallet

3.Filled with polyfoam, fit well between the furnace body and the case in all sides

4.Easy-to-identify double-sided outer box print logos and shippment marks

Delivery Time: 15 working days against receiving advanced payment

Port: Shanghai/Qingdao

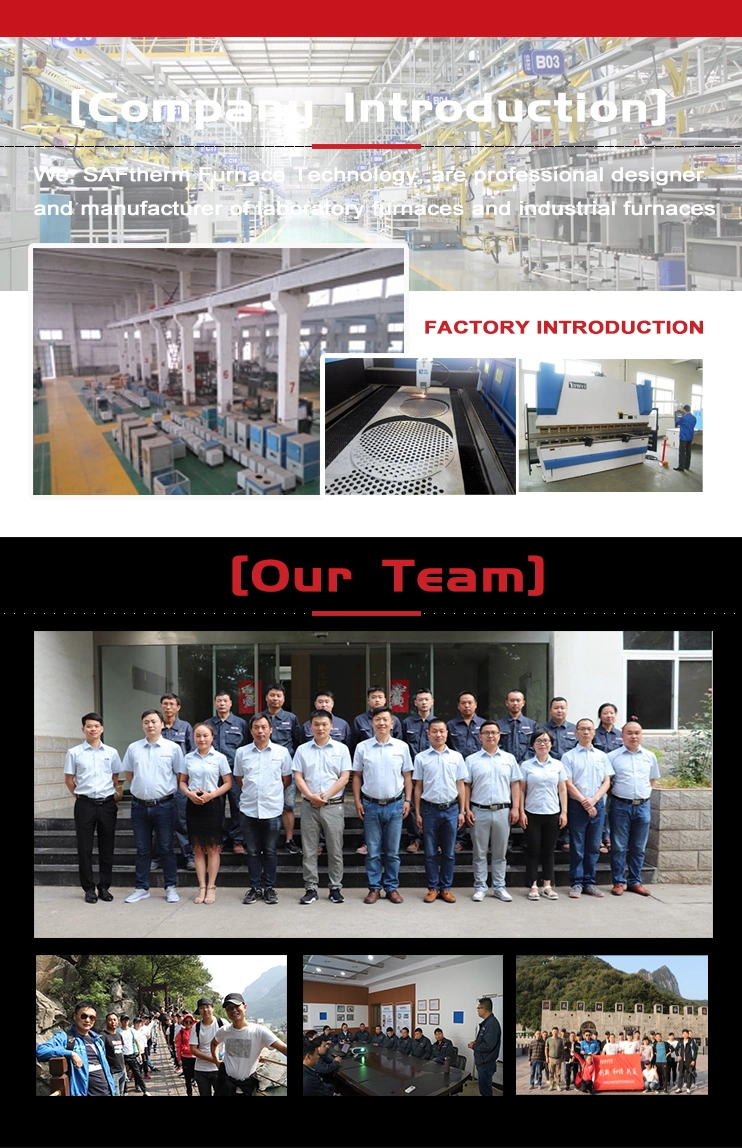

CertificationsFAQ1: Are you a factory?

Yes. We are China leading laboratory and industrial heating treatment furnace manufacturer, which integrates design, manufacture and sales for nearly 20 years.

2: Do you have customization or OEM service?

We can customize furnaces as product, work piece size, and temperature requirement. Meanwhile, we offer OEM service under the strict industrial standard.

3: What is the delivery time?

Normally within 15 working days after receiving the advanced payment or depends on order quantity.

4: How can you guarantee the production quality?

Firstly, we are ISO9001:2008 and CE certified factory, all the processes are strictly following the standard of the metallurgy process; secondly. We have QC department who perform strictly in each producing process including package.

5: How long is your furnace warranty period?

One year(expect thermocouple and heating element), lifetime support

6: What payment terms does SAFTHERM support?

T/T, L/C and so on.

Our Contact